How to do heating wiring correctly. Heating installation in private houses - we are considering possible options. Two-pipe top wiring

The design and installation of a heating system in a house can be carried out in a variety of ways. Already at the stage of drawing up the project, you should choose the most optimal option, which will help bring all the owner’s ideas into reality, without going beyond the planned budget.

The most financially profitable option is a single-pipe heating system. Two-pipe heating wiring may be somewhat more expensive, but the efficiency of this method is much higher.

Popular heating wiring methods

A fireplace or stove is very often placed in the modern interior of a private house, but they most likely serve a decorative function, emphasizing the individual style of the house, since the main heating load falls on one or two circuit heating boilers. The operating principle of a single-circuit boiler is solely to provide heating for the house, while a double-circuit boiler, in addition to heating the house, can also work as water heating.

Regardless of the type of heating boiler, to set up an individual heating system, you can use either a single-pipe wiring diagram or a two-pipe one. Let's look at their main features and try to figure out what the advantages and disadvantages of each type are.

Single-pipe heating system

The principle of operation of such a system is very simple: when installing heating, only one pipe is installed, which creates a vicious circle. This system is connected to batteries from every room in the house.

There are two ways to set up such a system:

- horizontal;

- vertical.

The horizontal method of arranging a single-pipe heating system with bottom wiring is more popular, as it has a fairly simple design. A special feature is the special installation method, in which the installed pipes must have a slight slope so that the coolant can easily circulate throughout the entire system.

The nuances of installation using the horizontal method arise when heating is installed in a multi-storey building. Then, at the entrance to the initial section of the radiator, located on the ground floor, you need to install a valve, partially closing which you can create the necessary pressure for coolant circulation on the upper floors.

Attention ! When arranging the vertical distribution of heating pipes in a private house, it is very important to take into account the location of the risers. It should only be vertical, and the pipes should have a slightly larger diameter than when installed in a horizontal layout.

One of the advantages of a one-pipe heating system with bottom wiring is the absence of the need for a mandatory connection to a circular pump.

Advantages of single-pipe heating:

- good savings on materials, as fewer pipes are required;

- very simple and clear wiring diagram;

- clear calculation of hydraulic load on pipes.

But, unfortunately, despite all the positive aspects, they are completely negated by one minus. It consists of a significant loss of coolant temperature as it moves away from the heating boiler. This means that the radiators in the farthest rooms will be slightly warm.

This situation can be corrected in the following ways:

- increase the total number of sections in the radiator as it moves away from the boiler;

- install special thermostatic valves on the radiators that regulate the coolant supply pressure to each radiator;

- install a circular pump that will maintain the pressure at the required level and facilitate the correct distribution of the coolant throughout the network.

Single-pipe heating distribution in a private house will be optimal for arranging a heating system in a one-story private house with an area of no more than 100 m², and no additional devices such as “warm floors” will be needed.

Two-pipe heating system

The main difference between this type of heating system arrangement and the previous one is that each battery is connected to the main pipe of both forward and reverse current. This feature approximately doubles the pipe consumption. But it is worth noting the positive aspects. The owner of the house can independently regulate the level of heat supply to each radiator. As a result, you can easily create a pleasant atmosphere in every room.

The arrangement of a two-pipe heating system provides for several different wiring methods. Let's look at each of them in more detail.

Vertical scheme with bottom wiring

The technological process of installing a two-pipe heating system with bottom wiring includes the following steps:

- A main pipeline is installed along the floor of the first floor or basement, which originates from the heating boiler.

- Vertical pipes are carried along the main pipe, which ensure the movement of coolant to the radiators in the rooms.

- Each radiator must have a pipe installed for the return flow of cooled coolant into the heating boiler.

When designing a two-pipe heating system with bottom wiring, you must definitely think about how exactly the need for regular air outlet from the pipeline will be ensured. As a rule, this requirement is met by the installation of an air pipe, an expansion tank and the installation of Mayevsky taps on all batteries, which are located on the second and third floors of the building.

Vertical scheme with top wiring

This model provides that the coolant is supplied from the heating device to the attic through a pipeline. From there, the coolant flows through the risers to all the radiators of the house. And the already cooled water returns to the heating boiler through the main pipeline.

Attention ! In order to avoid air congestion in the system, it is important to periodically remove air. To do this, install a special expansion tank.

The presented method of arranging a heating system at home is in many ways more effective than the method with lower wiring, because much greater pressure is supplied through the risers.

Horizontal heating system

Arranging a horizontal heating system with forced circulation is a very popular way to heat a house.

When installing horizontal heating, several schemes are traditionally used:

- Dead end. The advantage of this option is the economical consumption of pipes. The disadvantage is that the length of the circuit is very long and this makes it very difficult to regulate the operation of the entire system.

- Associated movement of water. All circulation circuits are of equal length, and this helps to adjust the system easily and simply. The disadvantage of this heating layout for a private house is the high consumption of pipes, which, due to their cost, significantly increase the repair budget and also spoil the interior of the premises.

- Collector or radial wiring of the heating system. Thanks to the fact that each battery is connected individually to the central heating distribution manifold, it is very easy to ensure uniform heat distribution. The disadvantage, as in the second case, is the very high consumption of materials. But all pipes are mounted into the wall, which does not spoil the interior of the room. Today, this heating distribution scheme for a private house is gaining popularity among developers.

When choosing a wiring diagram, it is important to take into account many factors: area of the building, types of construction materials, etc.

The heating system piping of a private home can be done with your own hands or with the help of specialists. In any case, a heating network project is first prepared, an important point in the development of which is determining the method of pipe routing.

The main elements of any heating network are: a heat-generating device, a main pipeline, heat-dissipating, compensation devices and a device that ensures coolant circulation. Heating pipelines can have different configurations and degrees of technical equipment.

Heating systems are classified according to three parameters:

- number of pipe circuits of the main pipeline,

- type of compensation device,

- type of circulation.

One- and two-pipe systems

The heating system can be:

In the first case, the coolant moves along one pipe circuit, alternately passes through all the heat-releasing devices, arriving at each increasingly cooler. The part of the main pipe after the last heat exchanger is called the return pipe or return pipe and serves to drain the cold working medium back to the heat generator.

In a two-pipe system, the energy carrier circulates through two parallel circuits: supply and return. The first circuit supplies hot coolant to each heat-releasing device, and the second circuit collects the cooled working medium from the heat exchangers and takes it to the heating device.

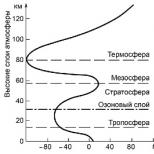

Types of circulation in heating systems

Heating of the premises occurs only if the coolant moves along the circuit. Circulation can be either natural or forced.

- In systems with natural circulation, the energy carrier heated by a heating device is accelerated to give it an impulse sufficient to pass through the entire thermal circuit. To do this, immediately after the heat generator, an accelerating manifold is installed - a vertical section of pipe, when descending from which the working medium picks up speed under the influence of gravity.

- Forced circulation is created by special circulation pumps installed on the return pipe. Such a system ensures the movement of coolant along a circuit of any length and complexity, but is completely dependent on the availability of electricity and stops working when the power supply is turned off.

Types of compensation devices

Depending on the method of compensating for pressure differences of the working medium in the circuit, there are two types of heating systems: open and closed.

- In an open system, the pressure is controlled by a compensation tank, partially or completely open. When the pressure in the heating network increases, the excess working medium enters the tank, and when it decreases, it goes back into the pipeline.

Note! In an open-type heating network, the working medium is in contact with the surrounding air, therefore a compensation tank is installed only on water heating systems.

- In a closed system, the expansion tank is sealed and has two autonomous compartments separated by a membrane. The operating principle is the same, but the coolant, entering the first compartment, does not come into contact with the environment, but interacts with the valve. When there is excess pressure, the working medium presses on the membrane, compressing the air in the second compartment; when the pressure returns to normal, the air in the second compartment is rarefied and squeezes the coolant back into the pipeline.

(CO) future home. A huge amount of information is poured onto him from TV screens and advertising billboards about new heating methods, which are just marketing ploys of sellers. This publication will describe the working diagrams of heating systems in a private house, their pros and cons, and discuss issues of choice for a country house.

Varieties and methods

As you know, there are three main options for autonomous heating of your own home: water, air and electric systems. In practice, everything happens as follows:

- If the building is located near the gas main, then the issue, as a rule, is resolved in favor of water heating with the installation of a gas boiler unit.

- If it is not possible to connect gas, then most developers purchase solid fuel heat generators with a water circuit.

- If it is impossible to install gas, and a solid fuel boiler is unacceptable due to the low degree of automation, then, for the most part, the same water heating system is installed, but complete with an electric heater.

And only when, for some reason, these options are not suitable, the developer chooses electricity, and even more so air, as a coolant. Why do most people choose water CO at home? Because this is the most proven and effective technology for solving the issue. But the efficiency of water heating depends not only on high-quality materials and equipment with high efficiency. It is very important to choose the correct wiring option. The installation of a heating system in a private house requires the presence of a strictly defined layout and connection of pipelines, radiators and other equipment.

Mounting options

Today, experts distinguish between two technologies for creating CO:

- Scheme

In a private house, it involves connecting all batteries (input and output) to one pipe, which is both supply and return.

This technique has been used since the beginning of the last century. Some experts believe that this technology gained popularity after the Great Patriotic War, as an alternative when there was a shortage of materials. Although many experts predicted its abandonment back in the 70s of the 20th century, it is successfully used today.

- In a private house, water enters the batteries through one pipe and returns to the boiler unit through another.

This technology is considered the most modern, thanks to which it is possible to significantly increase the efficiency of CO operation, but requires more complex installation and hydrodynamic calculations. Despite this, today almost all apartment buildings, office and public buildings are equipped with CO made using this technology.

The choice of a private house depends on many factors: the area and architecture of the premises, the number of floors of the building, the equipment involved in the CO.

Single-pipe

This water heating scheme is a closed loop, which includes a boiler unit, a main pipeline, heat exchange devices (radiators, registers), and an expansion tank. In gravitational COs, coolant circulation occurs due to the different densities of heated and cooled water.

The principle of operation of heating with natural movement of water in the circuit is as follows: The coolant heated in the boiler rises along the riser, in the upper part of which an expansion tank is installed. After this, the water enters the accelerator, thanks to which the pressure necessary for circulation is created.

This CO distribution is not intended for multi-storey buildings and single-storey houses with a large area.

This CO distribution is not intended for multi-storey buildings and single-storey houses with a large area.Advice: Regardless of the presence and height of the accelerating manifold, for good circulation of the coolant, it is recommended to create a slope of the main pipeline of 5°; on the supply branch to the radiators; on the return line - towards the boiler unit.

With mechanical circulation of water, there is no need for an accelerating manifold; its function is performed by a circulation pump. It is mounted on the return circuit, directly next to the boiler plant.

The figure shows a version of a single-pipe CO with horizontal distribution and forced circulation. This scheme is successfully used for one-story buildings, with the number of radiators 5-7 pcs.

Vertical single-pipe CO with overhead wiring, designed for buildings with several floors, is quite popular. May have the following implementations:

Vertical single-pipe CO with overhead wiring, designed for buildings with several floors, is quite popular. May have the following implementations:

To answer the question of which heating system is more effective: one-pipe or two-pipe, it is necessary to study them in detail.

Two-pipe version

The main design feature of heating a private house with this method of execution is that each of the radiators is connected to a different pipeline: supply and return. This is what, according to many “professionals,” significantly increases the cost of the heating system. In fact, this design allows you to save on the number of shaped products and on the diameter of the main pipelines.

There are several schemes for implementing two-pipe heating:

- Horizontal.

- Vertical, with top wiring.

- Vertical, with bottom coolant supply.

In turn, the horizontal two-pipe design can have three implementations:

A. Dead-end or oncoming.

V. Poputnaya.

C. With radial distribution or collector. Figure A shows the difference between a one-pipe heating system and a two-pipe one, despite the similar horizontal implementation.

Figure A shows the difference between a one-pipe heating system and a two-pipe one, despite the similar horizontal implementation.Structurally, the simplest horizontal two-pipe circuit looks like this: A coolant supply pipe departs from the heat generator, which goes into each radiator. The cooled coolant from the batteries is removed through the second pipe - the return pipe, which returns it to the boiler unit.

Water circulation is ensured by a circulation pump; the expansion tank compensates for the expansion of the coolant when it is heated; the safety valve provides protection against high pressure in the circuit; shut-off valves on radiators serve to dismantle the latter; an air vent is required at the top point of the circuit to prevent airing of the system.

Horizontal types of CO are relevant for one-story buildings. Each of them has its own advantages and disadvantages:

- Dead-end wiring has a small consumption of expensive pipe. The disadvantage is the large length of the contour.

- Along the way, adjusting the operation of the CO is easily realized. The disadvantage is the high consumption of material.

- In the manifold wiring, each heating device is connected to the boiler with its own pair of pipes, supply and return, which makes it easy to adjust the heating of a specific radiator. The disadvantage is the high consumption of pipes and their rather complicated installation.

Vertical two-pipe CO systems with lower and upper wiring have shown themselves to be excellent in two- to three-story private houses. With top distribution, the coolant rises through the supply pipeline to the highest point of the circuit, after which it is distributed along the return risers, passes through all radiators and returns to the boiler installation. The main advantage of the upper wiring is the creation of higher pressure in the circuit.

With vertical bottom wiring, the coolant is supplied from a line located under the floor of the lower floor or in the basement of the house. Next, the coolant moves along vertical risers and radiators installed on them. Rising to the highest point, the cooled water in the batteries flows through the return riser into the boiler unit. The advantage of this approach is the higher temperature of the coolant entering the radiators. The disadvantage is the possible airing of the circuit.

Choosing the best scheme for a private house

Now that we have a general idea about the types of heating and circuit connection options, it remains to decide what to choose, a single-pipe or two-pipe heating system?

There is an opinion that the former are more economical, easier to install and repair, and require fewer materials for sale. In fact, these advantages are quite controversial. For example, when such a CO operates, the end batteries on the branch receive coolant that has already cooled down in the previous ones. To maintain the required air temperature in the rooms located at the end of the circuit, it is necessary to increase the number of sections, and this is an additional cost. And all this against the background of the complete impossibility of automation, which will be responsible for maintaining the temperature balance necessary for comfortable living.

In a two-pipe system, the temperature of the coolant supplied to the batteries is the same, so there is no need to increase the number of sections of distant radiators in the circuit. The separation of the supply and return branches makes it possible to automate through the use of thermostatic valves.

Important! In fact, both one-pipe and two-pipe wiring have a right to exist. It should be understood that the choice is up to the developer, but only an experienced specialist will help you make the right choice of heating system for a private home.

Installation of a heating system in a private house can be carried out in various ways. At the design stage, the most optimal option is selected to solve the problem of heating all rooms within the available budget. The least expensive financially is single-pipe heating installation in a private house. The two-pipe wiring method is more expensive, but the effect of operating such a heating system in a country house is also much greater. Let's take a closer look at the diagram and features of installation of heating pipes in both types of wiring.

The main line layout, made from heating devices installed in series, is called a single-pipe heating system. The coolant, which is water or antifreeze, enters the radiators one by one and gives off part of its heat each time. Thus, water of a lower temperature enters the radiator, which is in last place in this chain. To prevent this from affecting the microclimate in the room, increase the number of sections in the final battery.

There are technologies that allow you to optimize the operation of a single-pipe heating system. You can additionally install radiator regulators, thermostatic valves, ball valves or balancing valves. This equipment allows you to balance the heat supply. When one of the batteries is blocked, the operation of the remaining heating devices in the system is not disrupted.

Important! When installing a heating system with your own hands, you must carefully install taps on the bypass and on the connections of each radiator in order to be able to repair the battery without turning off the heat supply to the entire house.

Autonomous heating of one-story or two-story houses can be organized in the form of:

- horizontal system with forced coolant circulation;

- vertical system with natural, forced or combined circulation.

Horizontal single-pipe heating system

Otherwise, this heating system is called “Leningradka”. The figure shows a heating wiring diagram for a private house of this type.

The pipeline can be laid above the floor or built into its structure, but must be enclosed in thermal insulation in order to reduce heat transfer. Installation of the horizontal supply line is carried out with a slight slope directed in the direction of flow of the coolant. In this case, radiators should be installed at the same level. Mayevsky valves are used to remove air from the system.

When installing a horizontal single-pipe heating system in a two-story house, it is necessary to run a riser supplying coolant to the second floor up to the first radiator. Temperature adjustment is carried out using taps installed on each floor in front of the first battery.

Vertical single pipe heating system

In this heating system, you do not need to use a circulation pump, because the supply of coolant is ensured during its natural circulation. Independence from the availability of electricity is the main advantage of this system. The disadvantage lies in the use of large diameter pipes and the location of the distribution line strictly at a slope. It is clear that such a pipeline cannot decorate the interior of the house. The disadvantage can be easily eliminated by installing a circulation pump.

Two-pipe heating wiring requires more materials, which affects its cost. The volume of installation work also increases, and, accordingly, their price. However, such pipe laying ensures uniform distribution of the coolant throughout the entire heating system. This makes it easier to adjust and configure the heating system in accordance with the needs of the residents of the house. When installing modern boilers produced by foreign manufacturers, a two-pipe heating system is welcome, which facilitates the operation of the pump in the boiler.

An example of a two-pipe heating system

This is what the standard diagram of a heating system looks like, in which heating of the coolant is provided by a gas double-circuit boiler, which can be either chimney or turbocharged.

The diagram shows the principle of wiring the heating system lines and the water supply network, and the features of connecting radiators. The installation locations of control and shut-off valves are shown.

Important! When installing heating on several floors of a private house, self-bleeding valves are required, which are installed at the highest points of the heating system. If the heating installation is carried out in a one-story house, then these valves are installed on the last radiators, as well as on the heated towel rail, if available.

In this diagram, the radiators are connected to the sides. In addition to the side connection, other options are possible - bottom or diagonal. In this case, the choice of connection type is influenced by the type and size of batteries used.

Important! Do not forget about the regulating thermal taps installed at the inlet and outlet of the radiator. A drain valve is also necessary, which is located at the lowest point of the heating system.

Options for connecting radiators in an approximate view

The choice of heating wiring diagram (two-pipe or one-pipe) determines the flow of pipes required for laying the system. Private houses with a large area are equipped with a two-pipe heating system, into which a circulation pump is additionally installed. The temperature in each heated room is controlled using thermostats. If the budget is small, then a single-pipe heating system is installed. Houses with a heated area of up to 100 square meters can be equipped with heating systems that operate on the principle of natural circulation.

We hope that we were able to show the options for heating distribution in private houses, as well as the features of their installation. Designing heating systems is a complex operation, for which it is better to involve professionals. This will allow you to avoid annoying mistakes that may occur during operation of the heating system. In order not to eliminate errors and shortcomings, it is better to foresee everything in advance.

We have prepared for you an overview of the main heating schemes for private houses, comparative characteristics, advantages and disadvantages of each system. Let's consider gravitational and forced coolant movement systems, one-pipe and two-pipe wiring diagrams, and the integration of heated floors into the heating system.

Heating system designs are very diverse. Moreover, the choice of one of them should be made based on the design and size of the house, the number of heating elements, and dependence on the power supply.

Systems differing in the circulation method

In a system with natural circulation, the movement of the coolant is based on the action of gravity, which is why they are also called gravitational or gravity. The density of hot water is lower, and it rises, displaced by cold water, which enters the boiler, is heated and the cycle repeats. Forced circulation - in systems using pumping equipment.

Gravity system

The gravity-fed system does not work out cheaper, as developers expect. On the contrary, as a rule, it costs 2 or even 3 times more than forced. This scheme requires larger diameter pipes. For its operation, slopes are required, and the boiler must be lower than the radiators, i.e. installation in a pit or basement is required. And even during normal operation of the system, the batteries on the second floor are always hotter than on the first. To balance this imbalance, measures are required that make the system much more expensive:

- installation of bypasses (additional material and welding work);

- balancing cranes on the second floor.

This system is not suitable for a three-story building. The movement of the coolant is “lazy,” as the experts say. For a two-story house it works when the second floor is full, the same as the first, plus there is an attic. An expansion tank is installed in the attic, to which the main riser, preferably strictly vertical, is supplied from a boiler installed in a deep pit or in the basement. If in some places you have to bend the riser, this impairs the operation of gravity flow.

Horizontal pipelines (beds) with a slope are routed from the main riser, from which the risers are lowered and collected in the return line, which returns to the boiler.

Gravity heating: 1 - boiler; 2 - expansion tank; 3 — feed slope; 4 - radiators; 5 — return slope

Gravity heating: 1 - boiler; 2 - expansion tank; 3 — feed slope; 4 - radiators; 5 — return slope

Gravity-flow systems are good in buildings similar to the Russian hut and in one-story modern cottages. Although the cost of the system will be more expensive, it does not depend on the availability of power supplies.

When the house is attic, then installing an expansion tank causes a placement problem - it has to be installed directly in the living room. If people do not live in the house permanently, then the coolant is not water, but a non-freezing liquid, the vapors of which will enter directly into the living area. To avoid this, you can place the tank on the roof, which will lead to additional expenses, or you need to tightly close the top of the tank and lead the gas outlet pipe from the lid outside the living space.

Compulsory system

The forced circulation system is characterized by the presence of pumping equipment, and is now very widespread. Among the disadvantages of the method, one can note the dependence on the power supply, which can be solved by purchasing a generator for autonomous power supply when the network is turned off. Among the advantages, it should be noted greater adjustability, reliability and the ability, in some cases, to save money on organizing heating.

Pump connection: 1 - boiler; 2 - filter; 3 - circulation pump; 4 - taps

Pump connection: 1 - boiler; 2 - filter; 3 - circulation pump; 4 - taps

Various connection diagrams for pressure heating systems

There are several connection schemes for forced circulation systems. Let's consider the advantages, disadvantages and recommendations of experts on choosing a scheme for various buildings and systems.

Single-pipe system (“Leningradka”)

The so-called Leningradka is complex in calculations and difficult to implement.

Single-pipe pressure heating system: 1 - boiler; 2 - security group; 3 — radiators; 4 - needle valve; 5 - expansion tank; 6 - drain; 7 - water supply; 8 - filter; 9 - pump; 10 - ball valves

Single-pipe pressure heating system: 1 - boiler; 2 - security group; 3 — radiators; 4 - needle valve; 5 - expansion tank; 6 - drain; 7 - water supply; 8 - filter; 9 - pump; 10 - ball valves

With such a system, the filling of the radiator is reduced, which reduces the speed of movement of the medium in the battery and increases the temperature difference to 20 ° C (the water has time to cool down significantly). When installing radiators sequentially in a single-pipe circuit, a large difference in coolant temperatures is observed between the first and all subsequent radiators. If there are 10 or more batteries in the system, then water cooled to 40-45 ° C enters the last one. To compensate for the lack of heat release, all radiators, except the first one, must have a large heat transfer area. That is, if we take the first radiator as a standard of 100% power, then the area of the subsequent ones should be larger by 10%, 15%, 20%, etc., to compensate for the cooling of the coolant. It is difficult to predict and calculate the required area without experience in performing such work, which ultimately leads to an increase in the cost of the system.

With the classic Leningradka, the radiators are connected from the main pipe Ø 40 mm with a bypass Ø 16 mm. In this case, the coolant after the radiator returns to the main line. A big mistake is connecting radiators not in transit, but directly from radiator to radiator. This is the cheapest way to assemble a pipe system: short sections of pipes and fittings, 2 pieces per battery. However, with such a system, half of the radiators are barely warm and do not provide sufficient heat transfer. Reason: the coolant after the radiator does not mix with the main pipeline. The way out is to increase (significantly) the area of the radiators and install a powerful pump.

Two-pipe collector (radial) heating wiring diagram

It is a comb from which two pipes extend to each radiator. It is advisable to install the comb at an equidistant distance from all radiators, in the center of the house. Otherwise, if there is a significant difference in the length of the pipes to the batteries, the system will become unbalanced. This will require balancing (adjustment) with taps, which is quite difficult to perform. In addition, the system pump in this case must be of greater power to compensate for the increased resistance of the balancing valves on the radiators.

Manifold circuit: 1 - boiler; 2 - expansion tank; 3 - supply manifold; 4 — heating radiators; 5 — return manifold; 6 - pump

Manifold circuit: 1 - boiler; 2 - expansion tank; 3 - supply manifold; 4 — heating radiators; 5 — return manifold; 6 - pump

The second disadvantage of the collector system is the large number of pipes.

The third drawback: pipes are laid not along the walls, but across the premises.

Advantages of the scheme:

- lack of connections in the floor;

- all pipes are of the same diameter, most often 16 mm;

- The connection diagram is the simplest of all.

Double-pipe shoulder (dead-end) system

If the house is small (no more than two floors, with a total area of up to 200 m 2 ), there is no point in building a hitch. The coolant will reach each radiator. It is highly desirable to think through and install the boiler in such a way that the “arms” - individual heating branches - are approximately the same in length and have approximately the same heat transfer power. In this case, before the tees dividing the flow into two arms, pipes Ø 26 mm are sufficient, after the tees - Ø 20 mm, and on the line to the last radiator in the row and bends to each radiator - Ø 16 mm. Tees are selected corresponding to the diameters of the pipes being connected. This change in diameters is a balancing of the system, which does not require adjustment of each radiator separately.

Differences in connecting dead-end and associated circuits

Differences in connecting dead-end and associated circuits

Additional advantages of the system:

- minimum number of pipes;

- laying pipes around the perimeter of the premises.

Connections “sewn” into the floor must be made of cross-linked polyethylene or metal-plastic (metal-polymer pipes). This is a proven, reliable design.

Two-pipe associated system (Tichelman loop)

This is a system that does not have to be adjusted after installation. This is achieved due to the fact that all radiators are in the same hydraulic conditions: the sum of the lengths of all pipes (supply + return) to each radiator is the same.

The connection diagram for one heating loop: single-level (at the same static height), with equal-power radiators, is very simple and reliable. The supply line (except for the supply to the last radiator) is made of Ø 26 mm pipes, the return pipeline (except for the outlet from the first battery) is also made of Ø 26 mm pipes. The remaining pipes are Ø 16 mm. The system also includes:

- balancing valves, if the batteries differ in power from each other;

- ball valves, if the batteries are the same.

The Tichelman loop is somewhat more expensive than the collector and dead-end systems. It is advisable to design such a system if the number of radiators exceeds 10 pieces. For smaller quantities, you can choose a dead-end system, but subject to the possibility of a balanced separation of the “arms”.

When choosing this scheme, you need to pay attention to the possibility of laying pipes around the perimeter of the house so as not to cross doorways. Otherwise, the pipe will have to be turned 180° and led back along the heating system. Thus, in some areas, not two pipes, but three will be laid side by side. This system is sometimes called a “three-pipe”. In this case, the ride becomes unnecessarily expensive and cumbersome, and it is worth considering other heating schemes, for example, dividing the dead-end system into several “arms.”

Connecting water heated floors to the heating system

Most often, heated floors are an addition to the main heating system, but sometimes they are the only heaters. If the heat generator for heated floors and radiators is the same boiler, then the piping on the floor is best done on the return line, using cooled coolant. If the floor heating system is powered from a separate heat generator, you need to set the temperature according to the recommendations for the selected heated floor.

This system is connected through a manifold, which consists of two parts. The first is equipped with valve control inserts, the other part is equipped with rotameters - i.e. coolant flow meters. Rotameters are available in two types: with installation on the supply and on the return. Experts advise: if during installation you forget which rotameter you bought, be guided by the direction of flow - the liquid supply should always go “under the seat”, opening the valve and not closing it.

Connecting heated floors on the return line: 1 - ball valves; 2 - check valve; 3 - three-way mixer; 4 - circulation pump; 5 - bypass valve; 6 - collector; 7 - to the boiler

Connecting heated floors on the return line: 1 - ball valves; 2 - check valve; 3 - three-way mixer; 4 - circulation pump; 5 - bypass valve; 6 - collector; 7 - to the boiler

When planning a heating system in your home, you need to weigh the pros and cons of each scheme in relation to the design of the house itself.